Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp+86 18621680941

In the rapidly evolving landscape of manufacturing and packaging, the demand for high-quality Extrusion Tubes continues to rise, driven by their versatile applications and enhanced performance characteristics. According to a recent market report by Grand View Research, the global market for extrusion products is expected to reach $290 billion by 2025, with a significant portion attributed to the increasing need for durable and lightweight materials in various sectors, including automotive, construction, and consumer goods. This surge in demand underscores the importance of identifying high-quality suppliers who can deliver innovative alternatives to traditional extrusion tubes. In this ultimate guide, we will explore the unique features of these alternatives, their applications, and key criteria for evaluating and sourcing from reputable suppliers, ensuring that manufacturers stay ahead in this competitive environment.

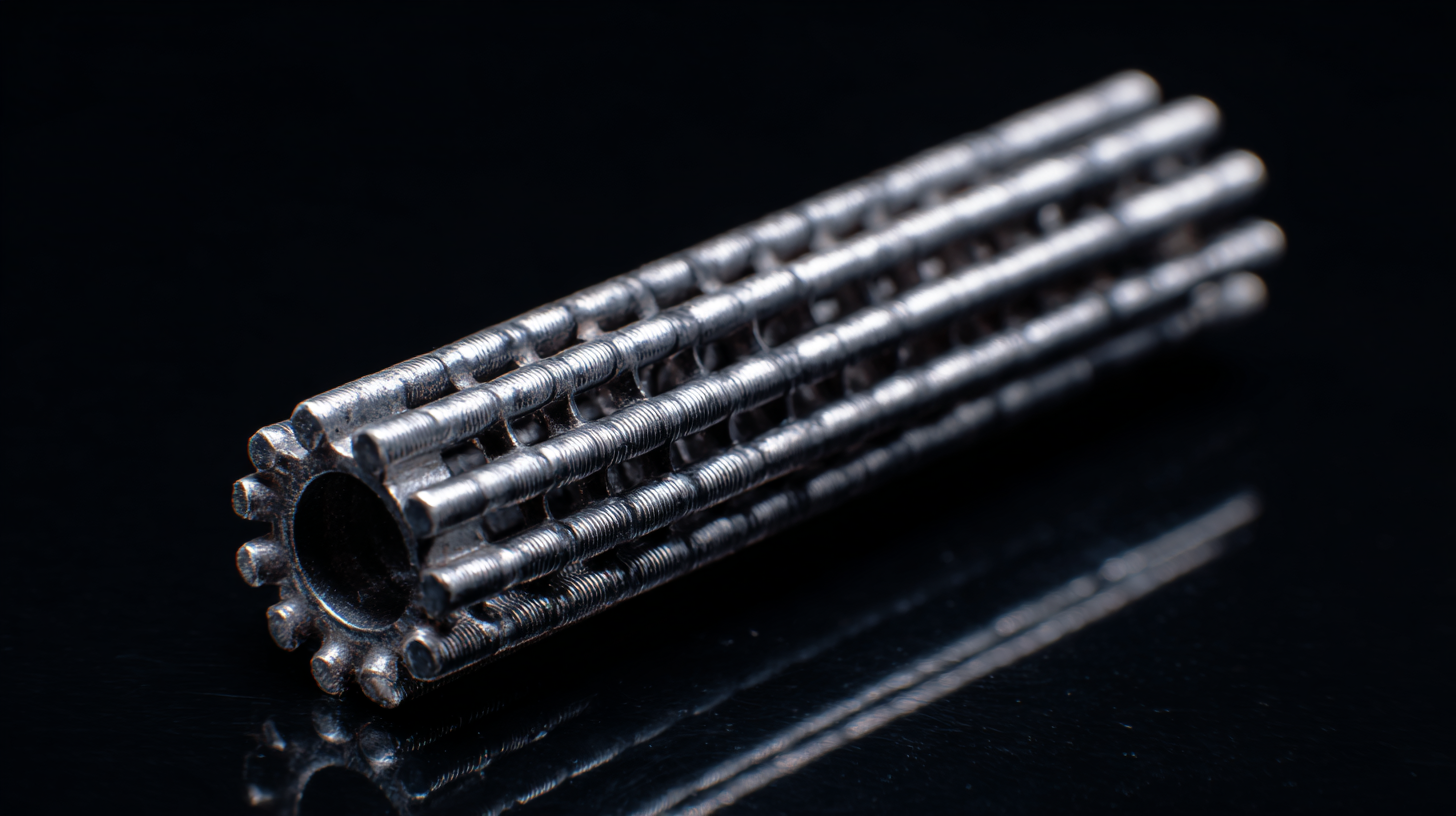

When delving into the world of extrusion tubes, it’s essential to grasp their fundamental concepts and the myriad benefits they offer. Extrusion tubes are hollow cylinders produced through a process where material is pushed through a die to create a uniform shape. This manufacturing method can utilize various materials such as plastics, metals, and composites, allowing for a wide range of applications across industries. The precision and consistency of extrusion tubes make them ideal for use in construction, automotive parts, and even in medical equipment.

One of the primary advantages of extrusion tubes is their ability to be tailored to specific requirements. This customization can include varying wall thicknesses, lengths, and diameters, providing designers with the flexibility necessary for innovative solutions. Furthermore, the extrusion process generates minimal waste, making it an environmentally friendly option compared to traditional machining techniques. Additionally, the durability and lightweight characteristics of many extrusion tube materials enable improved performance in demanding applications, standing out as a preferred choice for engineers and manufacturers alike.

| Material Type | Diameter (mm) | Wall Thickness (mm) | Temperature Resistance (°C) | Flexibility | Applications |

|---|---|---|---|---|---|

| Aluminum | 25 | 2.5 | 200 | Moderate | Manufacturing, Aerospace |

| Stainless Steel | 30 | 3.0 | 300 | Low | Food Processing, Chemical Industries |

| PVC | 20 | 1.5 | 60 | High | Plumbing, Electrical Conduits |

| Copper | 15 | 2.0 | 250 | Moderate | Electronics, Heat Exchangers |

| Polyethylene | 35 | 4.0 | 80 | High | Packaging, Agriculture |

When it comes to extruding materials, traditional extrusion tubes have long been the go-to solution. However, alternative options are emerging that provide distinct advantages. For instance, silicone tubing offers exceptional flexibility and resistance to high temperatures, making it ideal for food industry applications where hygiene and temperature consistency are critical. Similarly, PTFE tubing boasts excellent chemical resistance, making it suitable for transporting aggressive substances in various industrial processes.

**Tip:** When selecting an alternative, consider the specific requirements of your project, such as temperature ranges and chemical exposure. This will help in identifying the most suitable material for your needs.

Another noteworthy alternative is nylon tubing, which combines strength and lightweight properties, being particularly favored in automotive and aerospace applications. Furthermore, medical-grade PVC tubes provide a cost-effective solution for disposable applications, maintaining safety without compromising on performance.

**Tip:** Always evaluate the long-term resilience of your selected material. Conduct tests under real-world conditions whenever possible to ensure it can withstand the demands of your application.

In recent years, the demand for extrusion tube alternatives has surged across various industries, driven by their unique properties and versatility. These alternatives, such as 3D printed tubes, composite tubes, and engineered polymers, are being explored for innovative applications in sectors like aerospace, automotive, and construction. For instance, 3D printed tubes allow for complex geometries that can significantly reduce weight while maintaining strength, making them ideal for high-performance applications in aerospace.

Moreover, composite tubes, which combine materials to enhance durability and resistance to environmental factors, are increasingly used in automotive manufacturing. Their lightweight nature contributes to improved fuel efficiency without sacrificing safety or structural integrity. In the construction industry, engineered polymers offer excellent corrosion resistance, making them suitable for plumbing and electrical conduits in harsh environments. As these alternatives continue to evolve, their ability to offer customized solutions tailored to specific industrial needs demonstrates their pivotal role in modern manufacturing and construction practices.

When selecting the right extrusion tube alternative for your project, it is crucial to first consider the

material properties that will best suit your application. Many projects benefit from alternatives like PVC,

which offers excellent flexibility and chemical resistance, or aluminum, known for its strength and lightweight characteristics.

Additionally, understanding the environmental conditions, such as temperature variations or exposure to chemicals, can guide

your choice. Each material has unique attributes that can significantly affect performance, so

evaluating them based on project requirements is essential.

Another critical factor to consider is the manufacturing process involved. Some extrusion tube alternatives

may require specific fabrication techniques, such as bending or cutting, which could impact timelines and costs. For instance, while

plastic tubes can be more easily shaped and joined, metal tubes might demand specialized welding methods. Therefore,

assess your project’s capabilities and resources to ascertain whether you can accommodate the necessary techniques for your chosen material.

Tailoring your choice based on these considerations will ensure a successful outcome for your project while optimizing efficiency and effectiveness.

When it comes to utilizing extrusion tubes, maintaining optimal performance is crucial. Regular inspection of the tubes is essential to identify any signs of wear and tear. This includes checking for cracks, leaks, or blockages that could impair function. Additionally, using the appropriate lubricant can significantly enhance performance, allowing for smoother material flow and reducing friction. Implementing a routine maintenance schedule not only extends the lifespan of extrusion tubes but also ensures consistent quality in production processes.

Best practices for extrusion tube applications also involve selecting the right materials based on specific use cases. Various alternatives like thermoplastic elastomers or metals may offer superior durability and flexibility, depending on the industry. Moreover, temperature and pressure controls play a pivotal role in achieving desired outcomes—maintaining optimal temperature can prevent material degradation and ensure a smooth extrusion process. By adhering to these maintenance tips and best practices, manufacturers can significantly boost the efficiency and reliability of their extrusion tube applications.